Address: Steel Industry Zone, Laobian District, Yingkou City, Liaoning Province

Tel: 0417-3907766

Mobile: 18341738585

Mobile: 13314010101

Email: ykwynlcl@163.com

Raymond mill (model 4R, 5R, 6R, 7R) Raymond mill, also known as Raymond mill. It is suitable for all kinds of mineral powder preparation, coal powder preparation, such as raw ore, gypsum mine, coal and other materials of fine powder processing. The ramon mill produced by our factory is a kind of pulverizing mill introduced from abroad. The product adopts the advanced technology of the same kind of foreign products, and is updated and improved on the basis of the large Raymond mill. The equipment has higher efficiency, lower power consumption, smaller floor space and less one-time investment than the ball mill. Under the action of centrifugal force, the grinding roller is tightly rolled on the grinding ring, so when the grinding roller and grinding ring wear to a certain thickness, it does not affect the output and fineness of the finished product. The replacing period of the grinding ring of the grinding roller is long, which eliminates the disadvantage of the short replacing period of the vulnerable parts of the centrifugal grinder. The air separation flow of the machine is in the fan - grinding shell -- cyclone separator -- fan circulation flow operation, so less dust than high-speed centrifugal crusher, clean operation workshop, environmental pollution.

After years of practice and continuous improvement, the structure of R-type Ramon mill has been increasingly perfect, with high efficiency, low energy consumption, small floor space, less capital investment and environmental pollution-free advantages. Therefore widely used in metallurgy, building materials, chemical industry, mines and other minerals in the field of grinding materials processing, suitable for processing mohs hardness under seven, humidity under 6% of all kinds of inflammable and explosive mineral, such as gypsum, talc, calcite, limestone, marble, potassium feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, bauxite, iron oxide red, iron ore, etc., product fineness 440 microns to 613 microns (0.613 mm to 0.44 mm), through the analysis of the combination of machine and fan, can meet the requirements of different users.

History of grinding: in 1906, c.v. Grueber founded Curt Von Grueber machinery factory in the southern suburbs of Berlin. He used the patent obtained in the United States to produce the first Maxecon mill, which was used in the MOABIT power station in BEWAG, Berlin, as a coal grinding equipment with the power of 5T/H. Within a few years, nearly 600 mills were sold, which were used in different grinding fields. In the same period, BEWAG plans to build a more productive coal mill. E.C.Loesche took a stake in and ran the Curt Von Grueber machine factory, then decided to buy the U.S. patent for Raymond centrifugal ring roller mill and produced the first generation of the Raymond mill system. Its structure is in the center of the machine stands a rotating spindle with a plum rack. Three or more rotary grinding rollers are suspended on the rack. The rotating shaft rotates at a certain speed to drive the grinding roller to swing outward, and the grinding ring embedded in the inner wall of the barrel is pressed down under the drive of centrifugal force. When the material enters the grinding zone, it is carried to the front zone of the grinding roller under the action of the plow-type guide vane below the grinding roller. Because of Raymond mill coal slow roll grinding force (centrifugal force) is limited by a roller roller diameter and rotational speed, the grinding at the time is only applicable to soft, low ash and coal quality material with good sex of grinding, and Germany's coal is hard, ash content and high, need higher grinding force and the structure of Raymond coal mill is difficult to meet the requirements of grinding, hence Raymond coal mill not gained popularity in Germany. At that time, Ramon coal mill was just suitable for the pulverization requirements of coal quality in the United States, so ramon coal mill was widely promoted and applied in the United States.

Raymond mill for common milling equipment, mainly for the barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, bluestone, petroleum coke, chemical raw materials insulation materials such as mohs hardness is not greater than 9.3, and the humidity below 6% of non flammable and explosive mines, chemical industry, construction and other industries more than 280 kinds of materials of high fine powder processing.

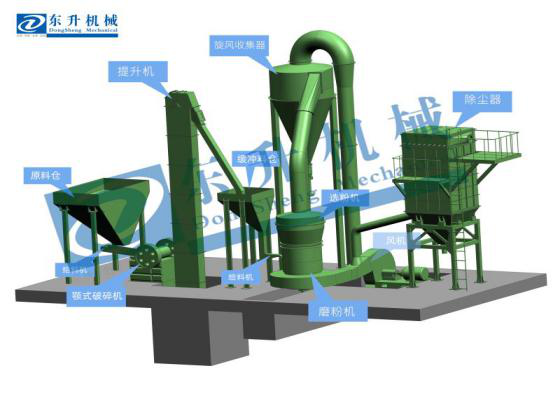

Main structure and working principle: The machine structure is mainly composed of main engine, analysis machine, blower, finished cyclone separator, piping device, motor, etc., among which the main engine is composed of frame, inlet volute, scraper, grinding roller, grinding ring, housing and motor. Auxiliary equipment includes jaw crusher, bucket elevator, electromagnetic vibration feeder, electric control cabinet, etc. Users can choose flexibly according to the site situation.

Raymond mill is working to break big block of raw materials to the feed particle size, the bucket elevator will material to the storage bin, and then by the electromagnetic vibration feeder evenly into the host by trituration, fan blowing air distribution plate into the grinding chamber, the grinding powder to analysis room, after the speed regulating motor through the analysis of the transmission device drives the rotating machine impeller sorting, large particle materials fall back into the grinding chamber, regrinding, qualified fine powder with airflow into the finished product cyclone powder, and air separation, from a discharge outlet for finished products. In the working process of the main machine, the material layer is crushed by the extruding pressure caused by the rotation of the grinding roller, so as to achieve the purpose of making powder.

Process characteristics

According to the processing technology of ultrafine powder equipment mastered over the years, people have carried out a comprehensive and thorough technical innovation to the above problems. When using the traditional Ramon mill, it is found that when processing calcareous ore powder, 325 mesh ore powder contains a large amount of 10um ultrafine ore powder. If it can be separated and the output can be expanded, the benefit will be greatly improved. To this end, a large number of updates and modifications have been made to the structure of Raymond mill:

The traditional mode of the main engine is improved, and the main shaft and plum blossom frame are improved to make them run stably.

No center swing. The traditional part of the analyzer is changed from the drag type in the cavity to the rotation and isolation in the transmission cavity by hanging hanging outside the cavity, so as to enhance its working stability and durability. In the grinding zone, the materials to be ground are always gathered in the grinding zone for effective processing, which improves the grinding efficiency. We also update the structure of the grinding roller, so that the grinding roller wheel and the grinding roller shaft can operate complementary. You can rotate while you rotate. Make it more efficient and durable. And it can operate with greater grinding power and higher running speed. In the ventilation part, the bellows and air ducts are changed from the raw water bottom to the center with an incline of 30 degrees, forming a bucket shape, to ensure that the bellows and air ducts are always unblocked and not blocked, so that the air volume is always needed and the main machine grinding powder is in high efficiency. In the whole system design, the traditional two-level collection is changed to four-level collection. The first and second level collection is closed with the circulation negative pressure lock, without dust overflow. The third and fourth level collection is controlled overflow dry and wet series collection, to prevent dust overflow. The whole system eliminates or reduces the pollution to the surrounding environment while collecting the ultrafine powder.

The new ramon mill can grind the nonmetallic minerals such as calcite, dolomite, talc, aged earth, barite, rutile, fluorite, etc. After practical testing, the calcaret with the feed size of 25mm is selected for grinding. When the fineness is adjusted to 1250 mesh (10um), the output can reach 450kg/h, while the input power only needs 23KW. Compared with the traditional Raymond mill has a significantly higher cost performance.

Maintenance:

1. In the process of using the ramon mill, fixed personnel should be responsible for watching, and the operator must have a certain technical level. Before the installation of the mill, the operator must have the necessary technical training, so that they understand the principle and performance of the mill, familiar with the operating procedures.

2. In order to ensure the normal operation of the Raymond mill, the "Safe operation system for Equipment maintenance" shall be established to ensure the long-term safe operation of the mill. Meanwhile, necessary maintenance tools, grease and corresponding accessories shall be required.

3. After the use of the ramon mill for a period of time, maintenance shall be carried out. Meanwhile, maintenance and replacement shall be carried out on wearing parts such as the grinding roller and grinding ring scraper.

4. When the grinding roller is replaced after using for more than 500 hours, each rolling bearing in the roller sleeve must be cleaned and damaged parts should be replaced in time. Manual refueling pump and butter gun can be used for filling tools.

5. The bearing shall be lubricated with No. 1 MOS2 grease or Zn-2 sodium bitter grease.

6. The grinding roller bearing shall be oiled once every shift, the center bearing of main engine shall be added once every four shifts, and the bearing of blower shall be added once a month. The temperature rise of bearing chamber shall not exceed 70 ℃. In case of overheating of bearing, the bearing and other accessories shall be removed for cleaning.

If R-type Raymond mill can be properly maintained, it will improve the service life and work efficiency of the mill. Please refer to the manual for maintenance, which is only for reference.

PREV:Vertical mill

NEXT:NO MORE